CED TANK VOLUME 9500 Litres

Our Tank Size is bigger than average in the industry, This Size can accommodate large & , complex Configuration Parts. Such as E-Rickshaw Chassis, Roof, Frames.

Services We Provide

We at Appex Industries specializes in providing best in class CED Coating Services which is advanced and environment friendly for a wide range of industries with any thickness requirement. Appex takes immense pride in our incorporation of top-of-the-line machinery and for using globally renowned paints & chemicals which also helps in building a sustainable future by having a compliance of ELV, REACH and ROHS specifically tailored to meet the demanding needs of our valued customers.

SCADA Control Process

The production process is Controlled using Scada Programs to achieve consistent Quality

Input Material

We use Best Grade Material for better paint Coverage & Smooth Finishes Approved By the Customers

Automatic Operations

CED Line Process i.e. Transporters, Spray & Dip Tank, Baskets, are operated automatically for accuracy.

Zero Coating Defects

Automated Process helps in defect free CED Coatings.

High Quality CED Coating

Coating Film thickness is controlled in Microns to achieve a properly scaled predefined requirements of our client’s.

High Corrosion Resistance

Our CED Coated Products Qualifies 960 Hours is Salt Spray Test (SST)

Quality & Testing

OUR STRENGTH

What We Coat

FOUR WHEELERS PARTS WE COAT

TWO WHEELERS PARTS WE COAT

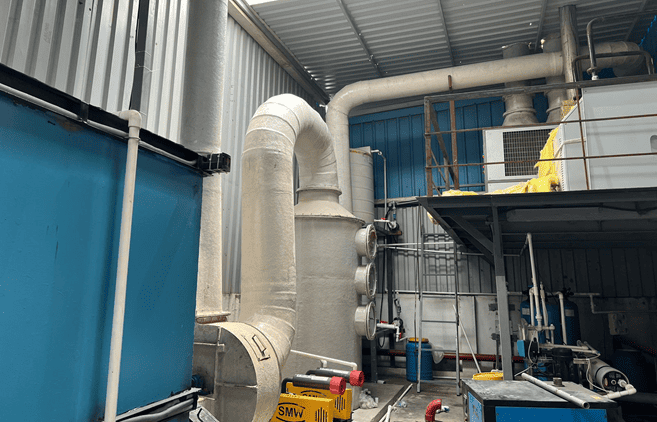

Gallery

A glimpse at our Unit and Equipment’s

Our Clients

Our Core Values

Appex always works keeping in mind society and customers.